limitation of hardness test|hardness testing standards explained : purchasing Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to . Hydrothermal Autoclave Reactormanufactured by Techinstro are elegantly designed, and are easy to operate; made from high-quality stainless steel structures that . See more

{plog:ftitle_list}

The rupture occurred in the Number 2 vessel which was growing synthetic quartz crystals at extremely high pressure and temperature. One piece of steel from the building was blown 650 feet, striking the driver who was walking .

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .

In this article, we briefly explained the importance and application, advantages .

what is hardness testing

static hardness testing

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.I. Why is the Vickers Hardness Test Significant? II. What are the Applications of Vickers Hardness Test? III. What are the Advantages of Vickers Method? IV. What are the Disadvantages of the Vickers Method? Conclusion. Introduction.Hardness of grinding wheels is measured by this testing method. Electromagnetic testing: Hardness is measured as a variable against. standards of known flux density. Ultrasonic testing: A type of indentation test. In the following chapters, most of these methods are covered.

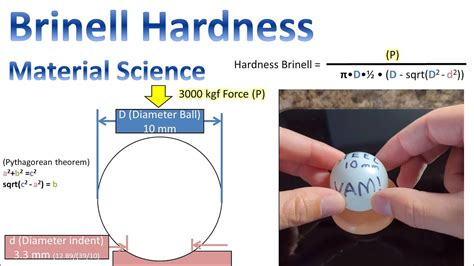

Understanding Hardness Testing: A Complete Guide | MachineMFG. Ever wondered why diamonds are so hard? In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in engineering.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests. The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and .Hardness test procedures of various types have been in use for many decades. They are usually quick and easy to carry out, the equipment required is relatively simple and cheap, and there are portable machines that allow in situ measurements to be made on components in service.

Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics. Each measurement shall not deviate by more than ±1% of the nominal test force for Brinell hardness (ISO 6506-1 2014), and each force measurement in the Vickers hardness shall not exceed the tolerance limit given in Table 1 (ISO 6506-2 2014). Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.I. Why is the Vickers Hardness Test Significant? II. What are the Applications of Vickers Hardness Test? III. What are the Advantages of Vickers Method? IV. What are the Disadvantages of the Vickers Method? Conclusion. Introduction.Hardness of grinding wheels is measured by this testing method. Electromagnetic testing: Hardness is measured as a variable against. standards of known flux density. Ultrasonic testing: A type of indentation test. In the following chapters, most of these methods are covered.

Understanding Hardness Testing: A Complete Guide | MachineMFG. Ever wondered why diamonds are so hard? In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in engineering.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests. The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and .Hardness test procedures of various types have been in use for many decades. They are usually quick and easy to carry out, the equipment required is relatively simple and cheap, and there are portable machines that allow in situ measurements to be made on components in service.

hardness testing standards explained

Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.

hardness testing scale

hardness testing process

hardness testing load definition

ceramic hardness testing

An autoclave is used for sterilizing equipment and materials, while a pressure cooker is used .Do you need further assistance in choosing an autoclave and pressure cooker for your growing .

limitation of hardness test|hardness testing standards explained